In today’s industrial environment, maintaining precise and efficient heating is critical for smooth operations. Many industries require high temperatures for processing, but steam boilers are not always the most efficient or safe option. This is where a thermic fluid heater becomes an ideal solution. Known for its high efficiency, safety, and uniform heat transfer, a thermic fluid heater is widely used across various industries.

At Durga Boilers & Engineering Works, thermic fluid heaters are designed to deliver consistent performance, long service life, and energy-efficient operation, making them a preferred choice for industrial heating applications.

What is a Thermic Fluid Heater?

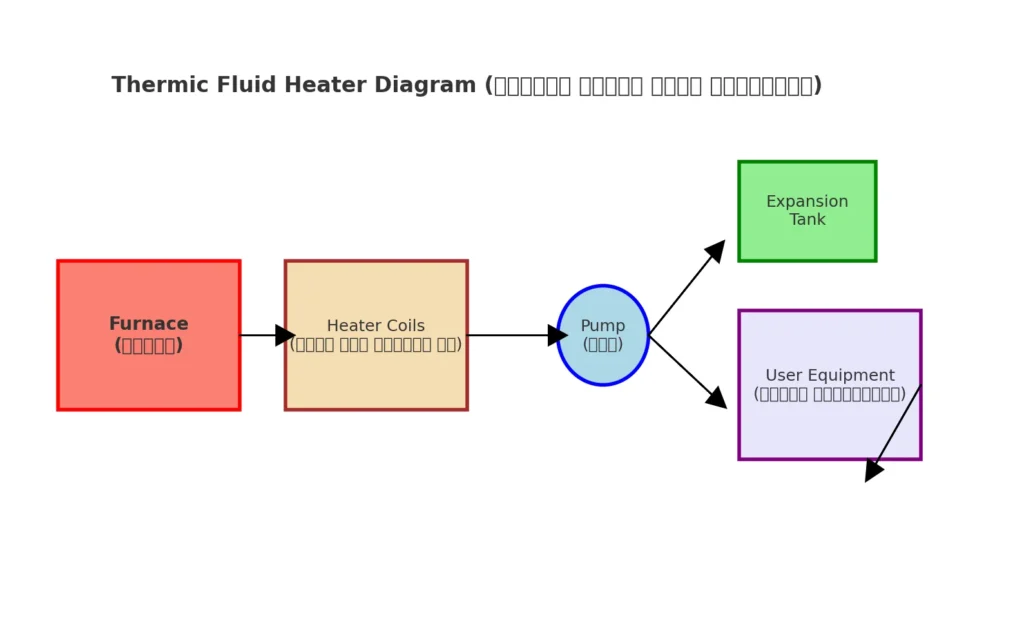

A thermic fluid heater is an industrial heating system that uses a heat transfer fluid instead of water or steam to deliver thermal energy. The fluid is heated inside a closed loop system and circulated to process equipment where heat is required. Unlike steam systems, thermic-fluid heaters operate at atmospheric pressure while still achieving high temperatures. This makes them safer, easier to operate, and more cost-effective for continuous industrial use. A thermic-fluid heater diagram typically shows a heater coil, expansion tank, circulation pump, and heat-consuming equipment connected in a closed loop, ensuring controlled and uniform heat transfer.

Thermic Fluid Heater Working Principle Explained

The thermic-fluid heater working principle is based on indirect heating. Fuel combustion does not come in direct contact with the process fluid or equipment. Instead, heat is transferred through a specially designed coil.

Fuel such as oil, gas, or solid fuel is burned in the combustion chamber. The heat generated is transferred to the thermic fluid flowing inside the coil. This heated fluid is then circulated to different parts of the plant where thermal energy is required. After releasing heat, the fluid returns to the heater for reheating, creating a continuous cycle. This closed-loop operation ensures stable temperature control, minimal heat loss, and improved system efficiency.

Thermic Fluid Heater Diagram – Understanding the System Layout

A thermic fluid heater diagram helps in understanding how the system functions as a complete unit. The diagram usually includes the heater coil, burner, expansion tank, circulation pump, control panel, and connected process equipment.

The expansion tank allows thermal expansion of the fluid, while the circulation pump ensures continuous flow. The control system maintains the desired temperature and ensures safe operation. This integrated design allows the thermic-fluid heater to perform efficiently even under demanding industrial conditions.

Flowchart

Thermic Fluid Heater vs. Steam Boiler – What Should You Choose?

When comparing a thermic fluid heater with a steam boiler, the choice depends on process requirements. Steam boilers are suitable for applications that require steam, but they involve high pressure, water treatment, and frequent maintenance.

Thermic fluid heaters, on the other hand, offer high-temperature operation at low pressure. They eliminate issues such as scaling, corrosion, and boiler explosions. The absence of water treatment systems and lower operating pressure makes thermic-fluid heaters a safer and more economical choice for many industries. For processes requiring precise and uniform heating, thermic-fluid heaters often outperform traditional steam boilers.

Industrial Applications of Thermic Fluid Heaters

Thermic fluid heaters are used in a wide range of industries where controlled heating is essential. In chemical and pharmaceutical plants, they provide accurate temperature control for reactors and distillation units. In textile and dyeing industries, they ensure consistent heat for drying and finishing processes. Food processing units rely on thermic fluid heaters for frying, baking, and sterilization. The plywood, paper, and packaging industries use them for pressing, drying, and curing applications. Their versatility makes thermic fluid heaters suitable for both continuous and batch processes.

Key Components of a Thermic Fluid Heater System

A thermic fluid heater system consists of several critical components working together to ensure efficient operation. The heater coil is designed to withstand high temperatures and transfer heat efficiently to the fluid. The burner provides controlled combustion based on fuel type.

The circulation pump maintains a steady flow of thermic fluid throughout the system. The expansion tank accommodates fluid expansion due to temperature changes. Advanced control panels regulate temperature, safety interlocks, and fuel supply, ensuring smooth and safe operation.

Each component plays a vital role in maintaining performance and system reliability.

Oil & Gas-Fired Thermic Fluid Heater

An oil & gas-fired thermic fluid heater uses liquid or gaseous fuels such as furnace oil, diesel, LPG, or natural gas. These heaters are known for clean combustion, quick startup, and precise temperature control. They are widely used in industries where fuel availability and emission control are important factors. Oil and gas-fired systems offer high thermal efficiency and are suitable for applications requiring continuous and stable heat supply.

Solid Fuel-Fired Thermic Fluid Heater

A solid fuel-fired thermic fluid heater uses fuels such as coal, briquettes, wood, or agro-waste. These heaters are ideal for industries looking to reduce fuel costs by using locally available solid fuels. Although they require more handling and ash management, solid fuel-fired thermic fluid heaters are cost-effective for long-term operation. With proper design and maintenance, they deliver reliable and efficient heating performance.

Choosing the Right Thermic Fluid Heater for Your Plant

Selecting the right thermic-fluid heater depends on factors such as required temperature, heat load, fuel availability, operating hours, and process type. It is important to choose a system that matches your plant’s specific needs to avoid energy loss and operational inefficiencies.

At Durga Boilers & Engineering Works, thermic-fluid heaters are designed and customized based on customer requirements, ensuring optimal performance and long-term reliability.

Thermic Fluid Heater Maintenance & Efficiency Tips

Regular maintenance is essential to ensure high efficiency and long service life of a thermic-fluid heater. Monitoring fluid quality, checking burner performance, and maintaining proper circulation help in avoiding overheating and degradation of the thermic fluid.

Efficient operation also depends on proper insulation, accurate temperature control, and timely inspection of system components. With correct maintenance practices, thermic-fluid heaters can operate efficiently for many years.

What Makes Durga Boilers the Right Choice for Thermic Fluid Heaters?

Durga Boilers & Engineering Works is known for manufacturing high-quality and reliable thermic-fluid heaters. The company focuses on robust design, fuel efficiency, safety standards, and customer satisfaction.

With years of industry experience, advanced manufacturing facilities, and strong technical support, Durga Boilers delivers heating solutions that meet diverse industrial requirements. Customized designs and dependable after-sales service make the company a trusted name in the boiler and heating equipment industry.

Conclusion: Invest in a Thermic Fluid Heater for Long-Term Efficiency

A thermic fluid heater is a smart investment for industries seeking safe, efficient, and precise heating solutions. With advantages such as low-pressure operation, high thermal efficiency, and versatile applications, thermic-fluid heaters outperform many conventional heating systems.

Whether you choose an oil & gas-fired or solid fuel-fired system, a well-designed thermic fluid heater ensures reliable performance and reduced operational costs. By partnering with Durga Boilers & Engineering Works, industries can achieve long-term efficiency, safety, and productivity.